With the Production module you can follow all company production processes from raw material processing to delivery of the finished product. It is structured in several phases:

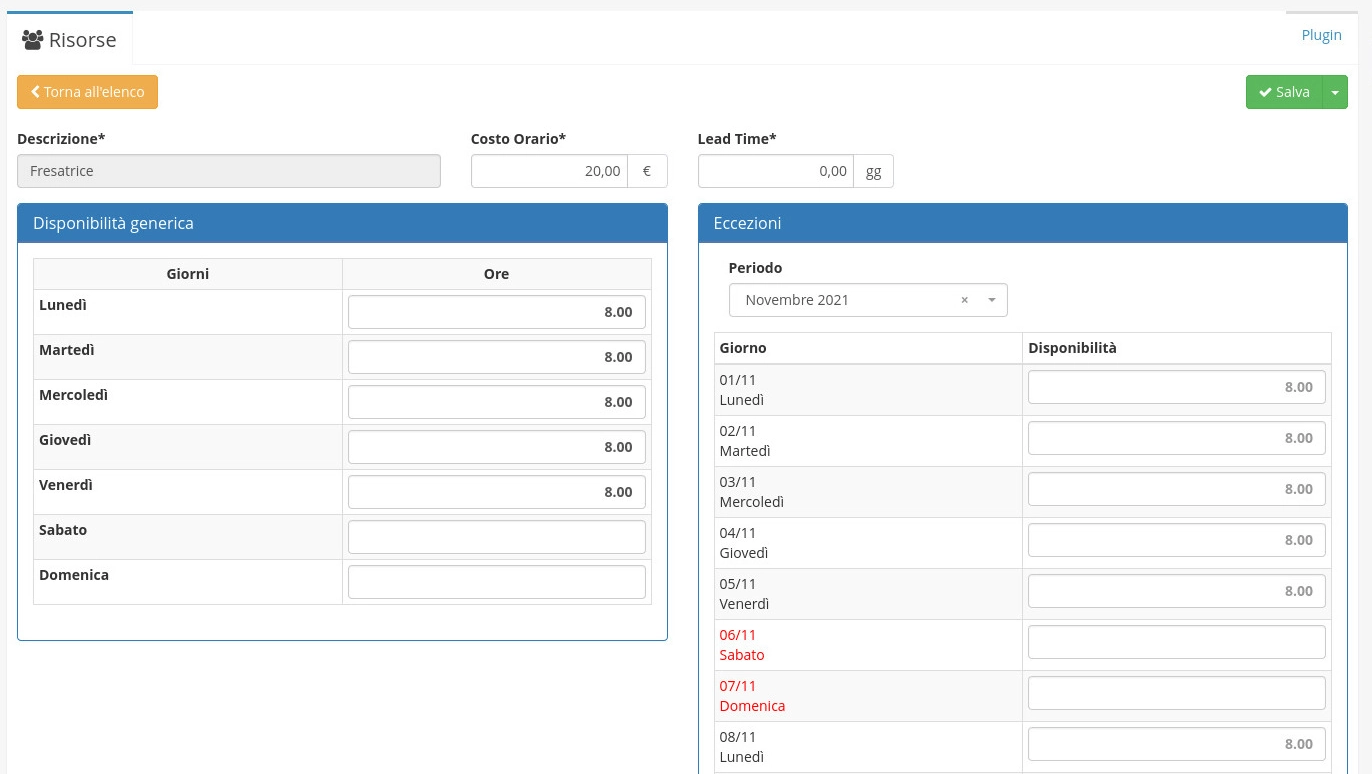

- Resources: manage the machinery used in production phases

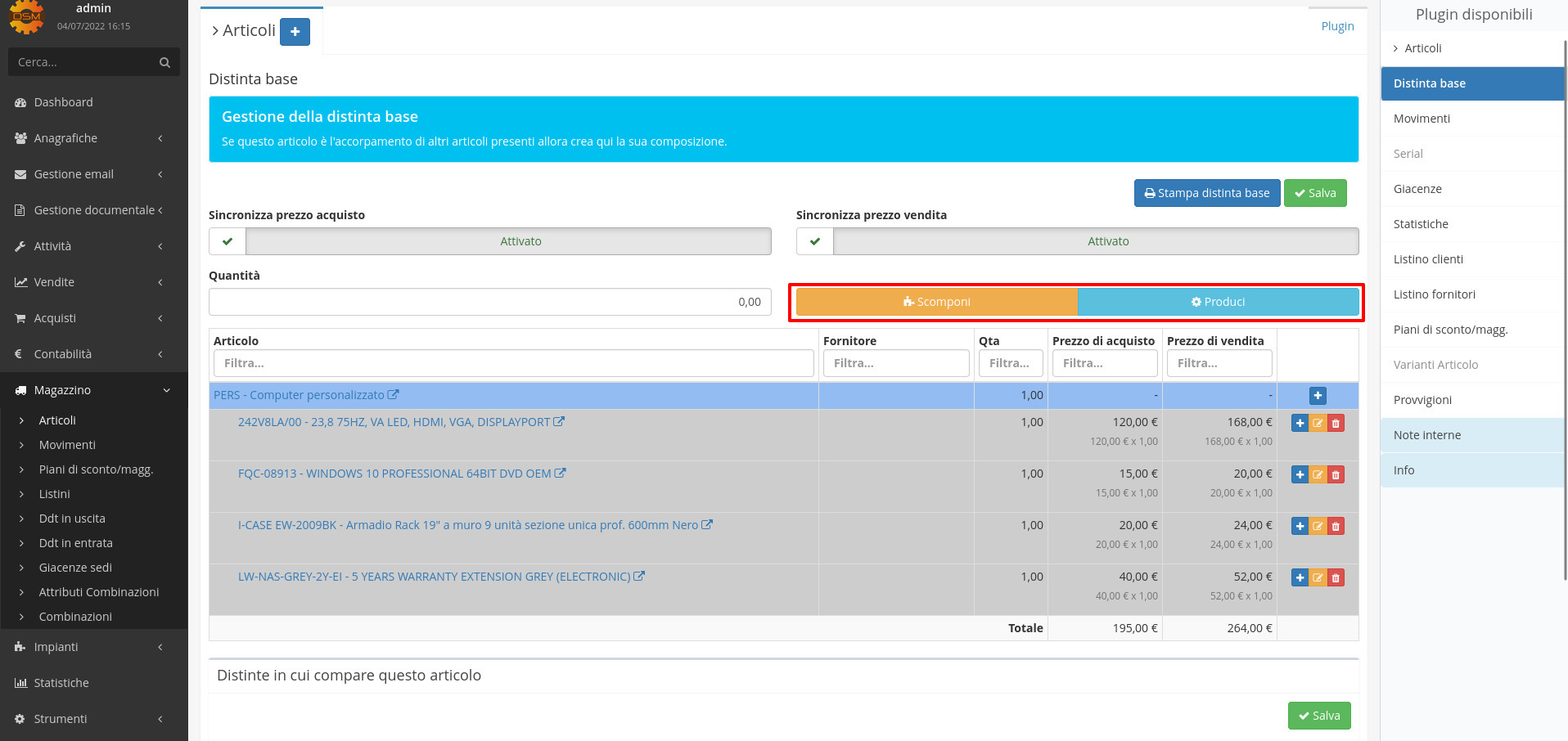

- Bill of materials: configure your products by connecting raw materials to assemble them

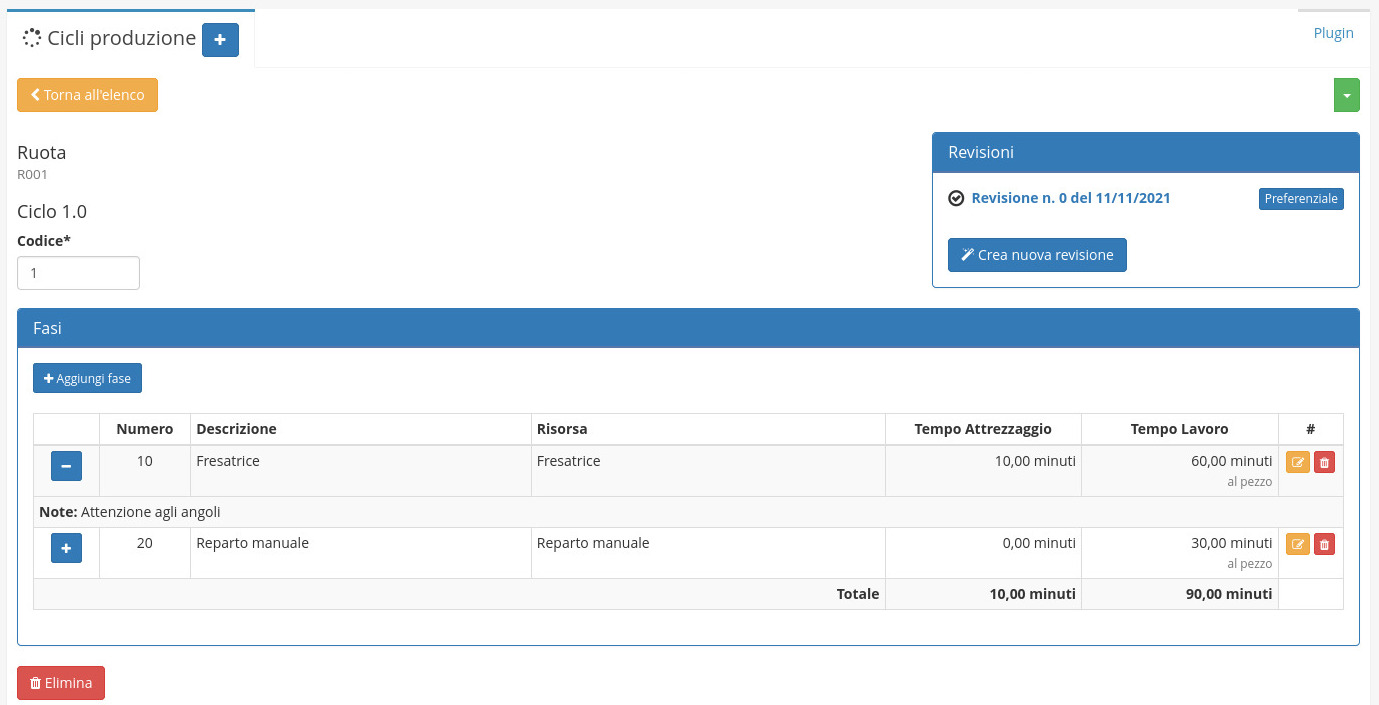

- Production cycles: define the various work phases and related resource usage

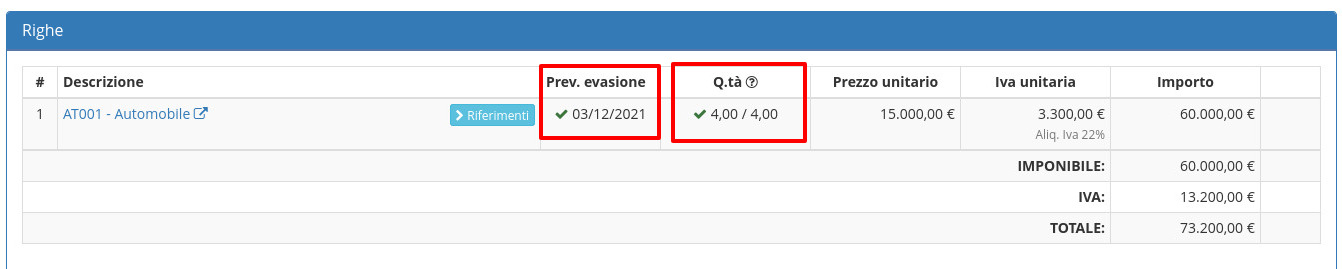

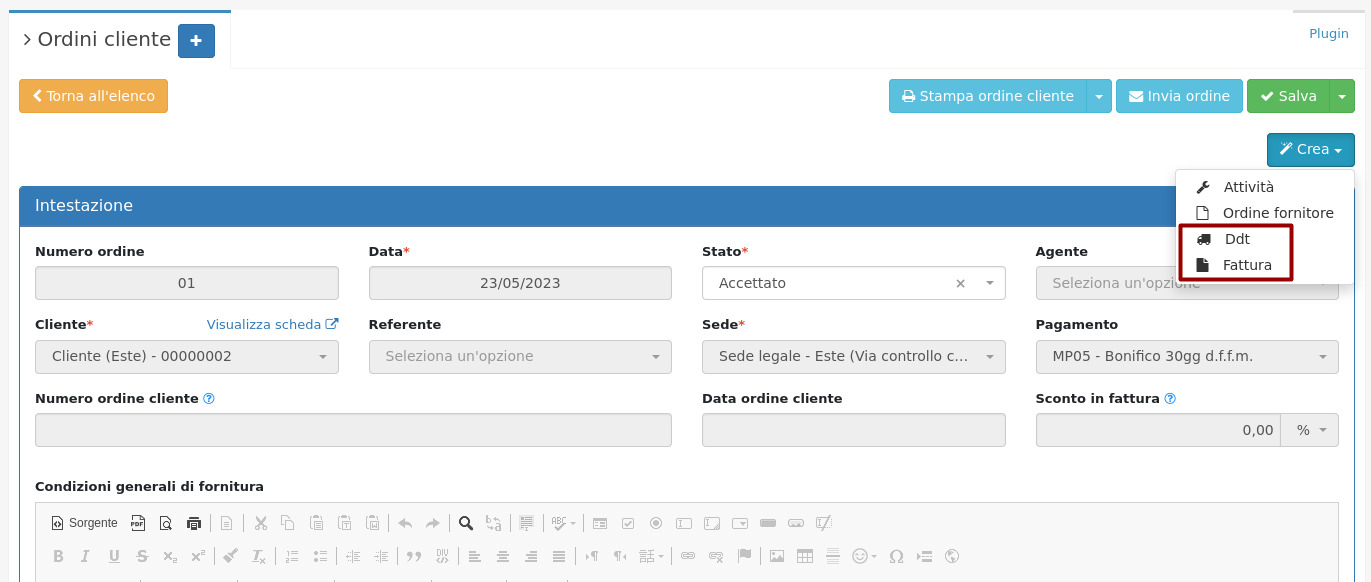

- Customer order: create customer orders on which to generate a work order

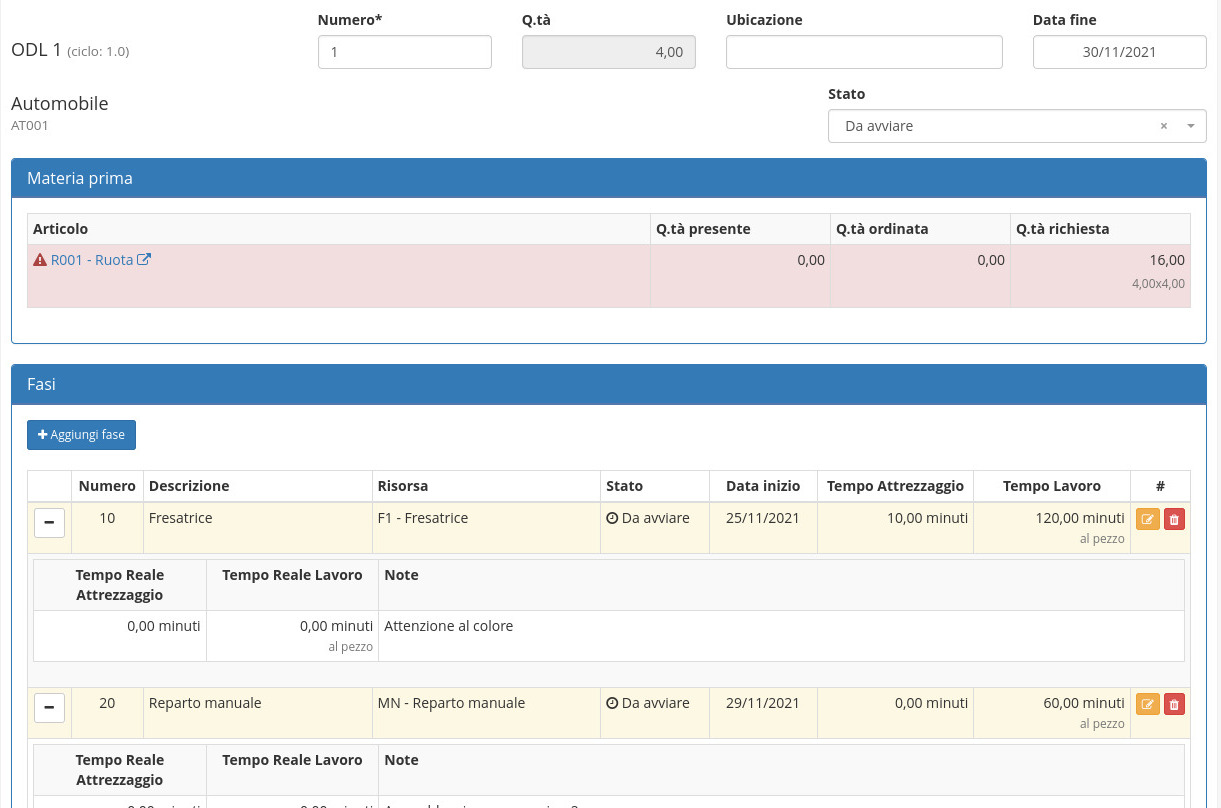

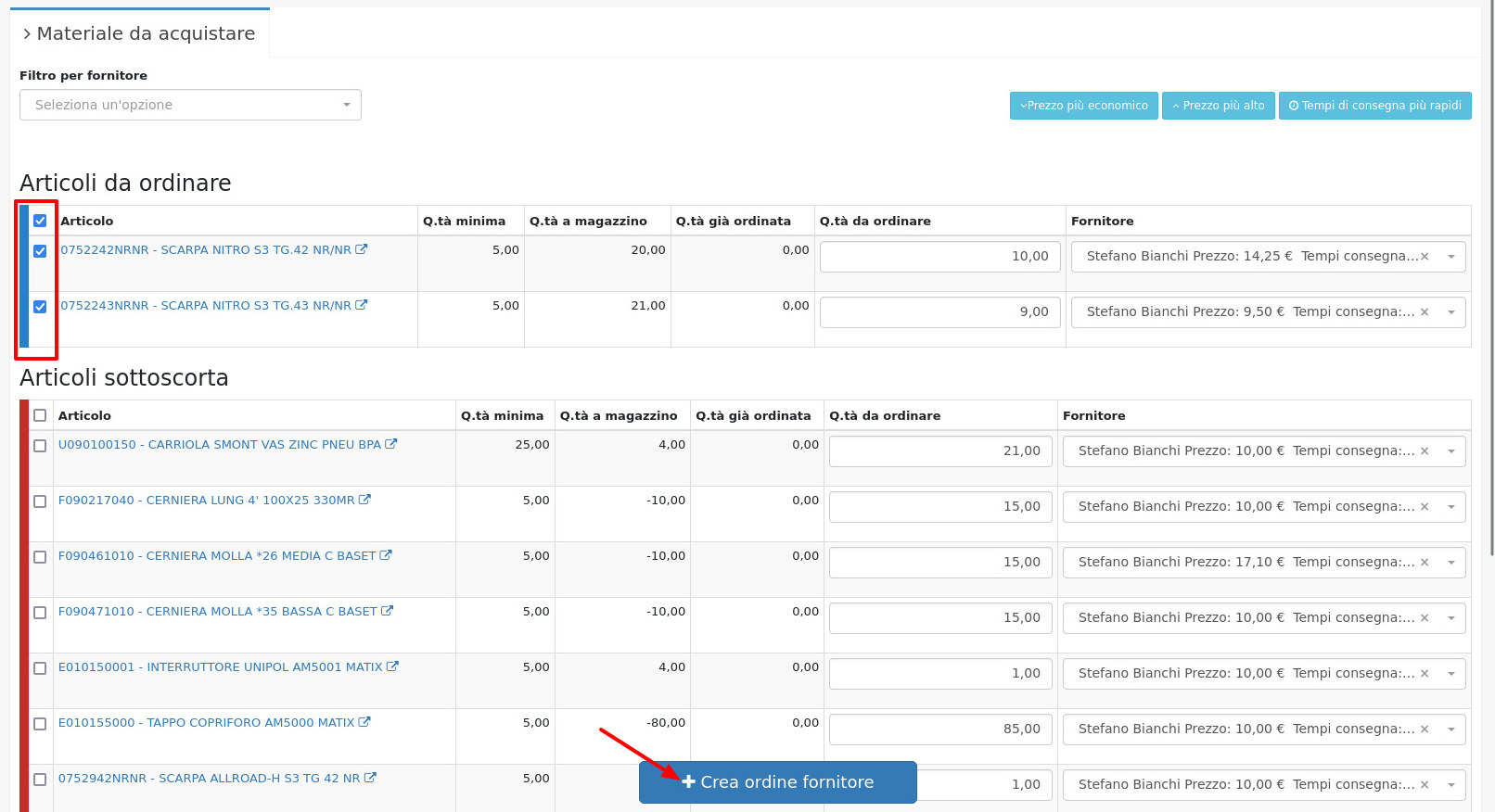

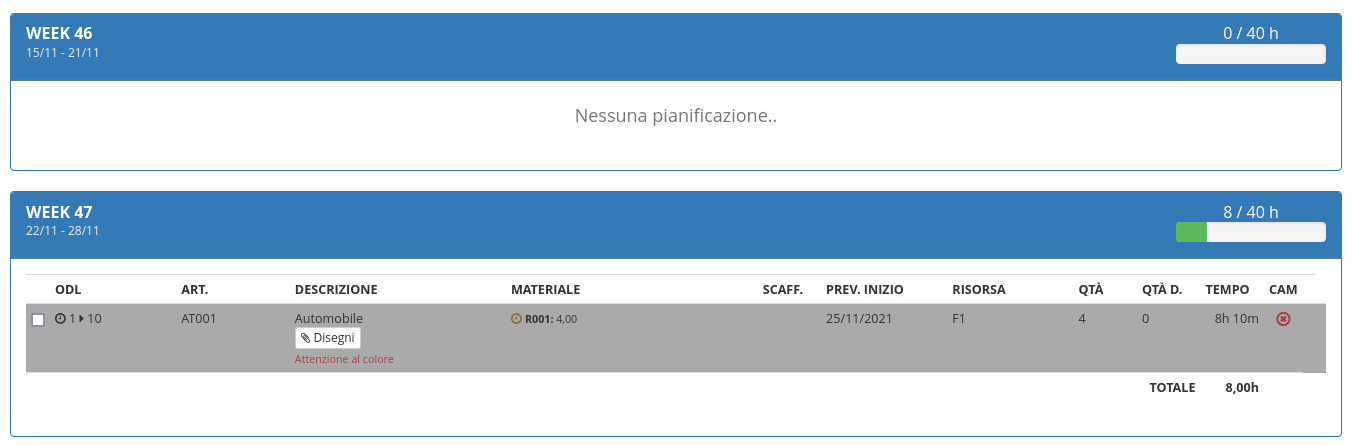

- Work order generation: manage work orders and automatically plan your departments

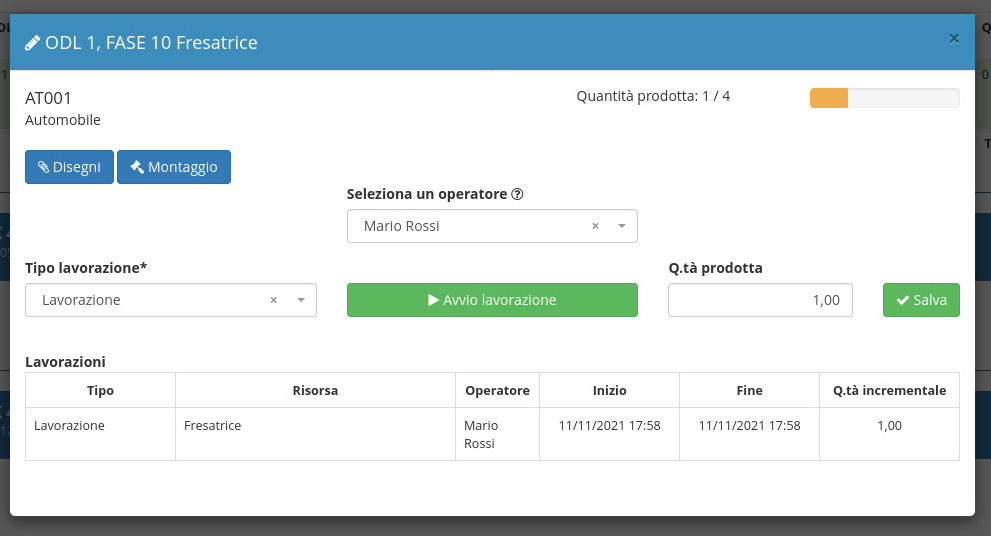

- Processing: declare produced pieces and actual processing times

- Shipping: create delivery notes and related invoices at the end of the month